The newest volume in The NRCA Roofing Manual series—The NRCA Roofing Manual: Architectural Metal Flashing and Condensation and Air Leakage Control—2026—was recently released. The new volume supersedes the previous edition published in 2022. The complete current NRCA roofing manual set consists of the following volumes:

- The NRCA Roofing Manual: Architectural Metal Flashing and Condensation and Air Leakage Control–2026

- The NRCA Roofing Manual: Steep-slope Roof Systems–2025

- The NRCA Roofing Manual: Metal Panel and SPF Roof Systems–2024

- The NRCA Roofing Manual: Membrane Roof Systems–2023

The new volume provides in-depth technical information concerning the design and installation of architectural sheet-metal components for low and steep-slope roof systems and moisture issues in roof assemblies.

The revised and updated volume consists of three parts: Architectural Metal Flashing section, Condensation and Air Leakage Control section, and Appendixes. Appendixes address energy code compliance for roof systems; moisture content of roof insulation; lightning protection systems interfacing with roof systems; unit conversions and reference organizations; and the NRCA technical dictionary.

Architectural metal flashing

Revisions introduced in the metal panel section of the 2024 roofing manual were carried over, including in Chapter 1—Guidelines Applicable to Metal sections that address:

- Background information about metal alloys used in the fabrication of architectural sheet-metal components of roof systems

- Protective coatings applied to sheet metal

- Exposed gasketed fasteners

- Joinery

The joinery section references newly added Appendix 5—Soldering Architectural Sheet Metal.

Also, throughout the manual, the use of decimal values replaces gauge numbers for specifying thicknesses of sheet steel materials such as galvanized steel, Galvalume® and stainless steel. The steel industry encourages the use of decimal thicknesses for specifying sheet steel products because there is no universally accepted standard that defines the thicknesses associated with each gauge number.

Information about lead-coated copper, zinc-tin-coated steel (Terne II) and zinc-tin-coated stainless steel (TCS II)—metal types no longer commonly produced—was relocated to the historical metals section.

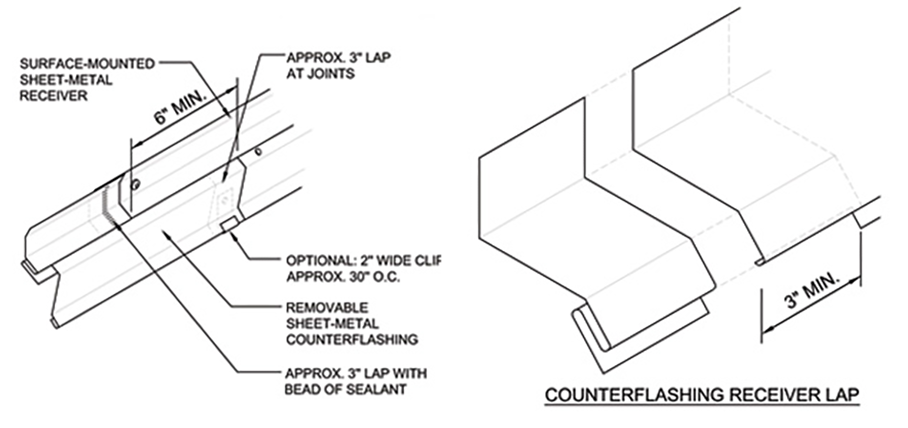

In Chapter 2—Guidelines Applicable to Low-slope Roof Systems, revised figures illustrating two-piece counterflashings—a receiver with a removable counterflashing—show the receiver back leg extended and the counterflashing fasteners moved from the receiver folds to the back leg. The figure shows the new configuration. A disassembled view of the counterflashing receiver end lap also was added. The same revisions are included in Chapter 3—Guidelines Applicable to Steep-slope Roof Systems and architectural metal flashings construction details.

Chapter 3 also includes revisions introduced in The NRCA Roofing Manual: Steep-slope Roof Systems—2025. A significant revision concerns NRCA’s position regarding the use of drip edge metal at eave and rake edges of steep-slope roof systems. NRCA recommends the use of drip edge metal at all eaves and rakes for asphalt shingle, metal shingle, slate, wood shake and wood shingle roof systems.

NRCA also recommends the use of drip edge metal at all eaves and exposed rake edges with clay and concrete tile roof systems. Exposed rake edges are those not finished with accessory rake tiles or other compatible rake trim materials.

Chapter 4—Construction Details recommends roofing contractors test fire-retardant-treated wood materials’ moisture content at the time of receipt for compliance with building code requirements. Section 2303.2.9 of the 2024 International Building Code® requires fire-retardant-treated wood to be dried before use to a moisture content of 19% or less for lumber and 15% or less for wood structural panels.

Architectural sheet-metal flashing construction detail updates include:

- New primary chimney cricket flashing detail

- Revised receiver construction and removeable counterflashing fastener placement for two-piece counterflashing options

- Two GT-1 tested shop-fabricated gutter details (one with internal and one with external reinforcing brackets)

ANSI/SPRI GT-1, “Test Standard for External Gutter Systems,” specifies test methods referenced in IBC 2021 and 2024 for gutters used to secure the perimeter edge of low-slope built-up, polymer-modified and single-ply roof membranes. NRCA has obtained approval listings for the new gutter details. An appendix in the architectural sheet metal section of the new manual volume addresses the code requirement, GT-1 test methods, and NRCA’s GT-1 testing and certification program.

Condensation and air leakage control

In Chapter 1—Fundamentals of Condensation and Air Leakage Control, Section 1.3 Climate Conditions includes an updated U.S. Climate Zone Map sourced from ASHRAE 169, “Climatic Data for Building Design Standards.”

In Chapter 2—Condensation Control for Low-slope Roof Systems, Section 2.1 Preventing Condensation Accumulation, NRCA recommends designers of low-slope roof assemblies with insulation primarily located below the roof deck include continuous above-deck insulation of R-5 to R-10. The additional insulation can protect those assemblies from condensation problems.

In Section 2.2 Determining the Need for a Vapor Retarder, NRCA recommends the use of a vapor retarder rated at maximum 0.01 perms over all concrete roof decks in climate zones 2 through 8. For new construction, the details should show exact locations of joints, interconnections, penetrations and termination point heights of the vapor retarder in the roof system design.

In Section 2.4 Vapor Retarder Materials, information was added about plastic sheet vapor retarders in insulated structural metal roof panel assemblies. Common methods of insulating below metal roof panel systems differ in how the plastic vapor retarder is configured and supported.

Some insulating systems use materials and sealing methods that may not provide vapor permeance ratings suitable for high-humidity interiors. Designers should consult the insulating system manufacturer to confirm the system is suitable for the intended application.

In the same section, new text addresses liquid-applied vapor retarders. Materials of this type are characterized by a wide range of vapor permeability ratings, depending on product, and tend to require a high level of application skill.

In Chapter 3—Condensation Control and Ventilation for Steep-slope Roof Assemblies, a revised discussion of attic and rafter space ventilation references research findings that quantify the cooling effects of ventilation on roof deck and roof covering temperatures. Also, a recommendation was added to maintain mechanical attic vents at planned regular intervals where an attic assembly relies on mechanical ventilation. Installers should remind building owners of this when installing mechanical attic vents to ensure reliable operation.

Chapter 4—Air Retarder for Roof Assemblies revisions include updated ASHRAE standard provisions for continuous building air barrier design, installation and testing.

Appendixes

Updated appendixes provide ASHRAE U.S. climate zones tabulated by state and county; 2021 ASHRAE Handbook Fundamentals winter and summer design temperatures for selected U.S. locations; NRCA commentary to the 2024 I-Code’s provisions for energy code compliance for roof systems; a brief discussion of hygrothermal modeling (a technique that uses software to simulate heat and moisture transport through building assemblies); and NRCA guidelines and practices for soldering architectural sheet metal.

Getting the new manual

Digital and hard copy versions of The NRCA Roofing Manual: Architectural Metal Flashing and Condensation and Air Leakage Control—2026 are available at shop.nrca.net. NRCA members can download the digital version free of charge.

MACIEK RUPAR

Director of technical service

NRCA