Ask roofing contractors, consultants and designers how long EPDM membranes last, and you’ll get remarkably consistent answers that align closely with four decades of scientific research.

In 2025, the EPDM Roofing Association conducted a comprehensive EPDM membrane service life survey of nearly 600 roofing professionals. Respondents reported firsthand experience with EPDM membrane roofs lasting 40, 45 and 50 years. They also expressed confidence EPDM roof systems will routinely deliver three to four decades of service when properly installed and maintained.

These aren’t marketing projections or optimistic estimates. The survey results represent accumulated field observations of professionals who inspect, design and install roof systems daily. When we compare these professional insights to the body of published research regarding EPDM membrane service life and extensive case studies, similar findings emerge.

What the survey says

The EPDM Service Life 2025 Survey captured insights from 240 roof consultants, 150 roof system designers and architects, 128 contractors and 51 “other” professionals. Respondents represent decades of collective experience evaluating, specifying and installing EPDM membranes across North America.

Expectations

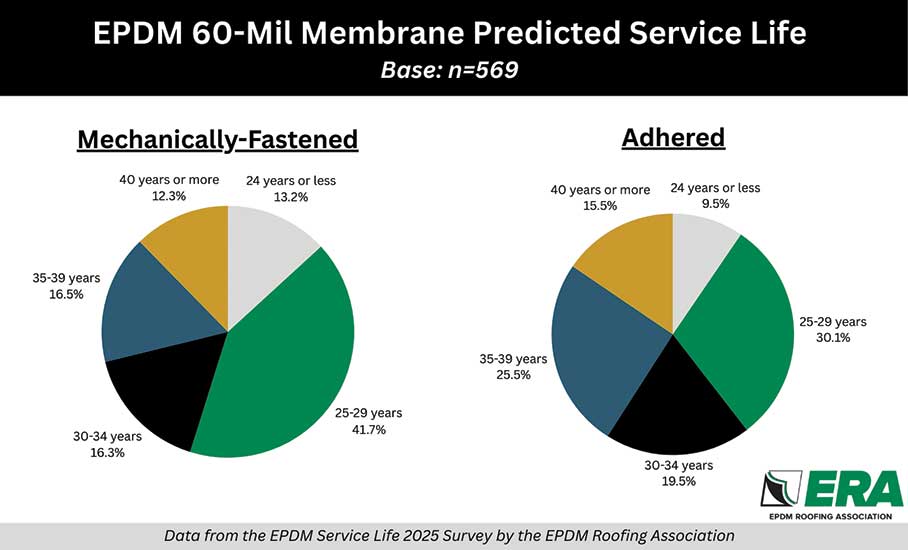

When asked about expected service life for properly installed and maintained EPDM roof systems, respondents were consistent in their responses and demonstrated a clear understanding of how membrane thickness and attachment method influence longevity.

For mechanically fastened 60-mil-thick EPDM membranes, 237 respondents (42%) predicted service life of 25-29 years, 94 respondents (17%) expected 35-39 years and 70 (12%) anticipated 40 years or more. The pattern held for adhered 60-mil-thick EPDM membranes though with slightly higher expectations: 171 respondents (30%) predicted 25-29 years, 145 (25%) expected 35-39 years and 88 (15%) expected 40 years or more.

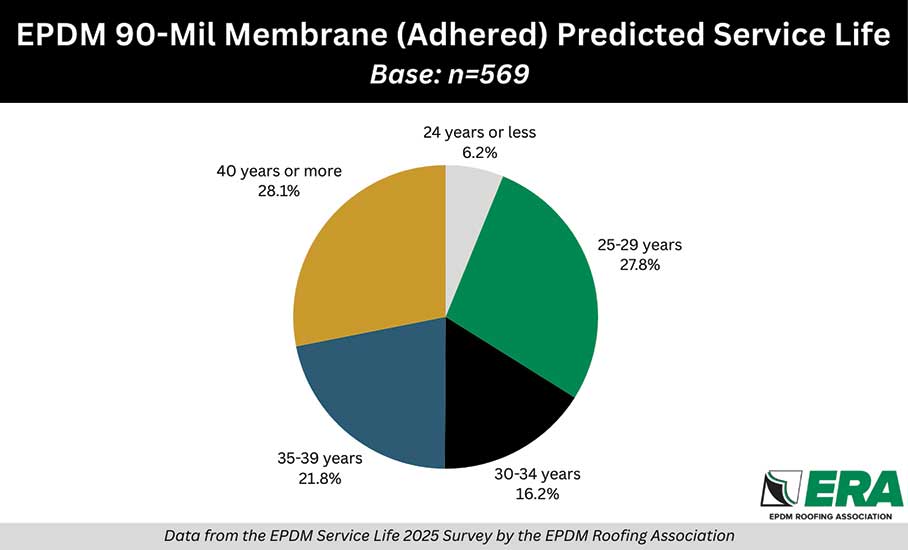

The expectations increased notably for thicker membranes. For adhered 90-mil-thick EPDM membranes, 160 respondents (28%) expected 40 years or more of service life, the most common response for any configuration surveyed.

The results reveal professional consensus among roofing professionals: An EPDM roof system has a service life range of 25 to 40-plus years with thickness and attachment method playing predictable roles when determining where within that range a specific installation falls.

Experience

When asked about the oldest (still in service) EPDM roof system they personally encountered, 23 respondents reported 30 years; 47 respondents reported 40 years; 20 respondents reported 45 years; and 21 respondents reported 50 years.

These observations extend beyond the oldest membranes documented in research literature, suggesting EPDM membrane installations can achieve service lives exceeding four decades in field conditions across diverse climates and building types.

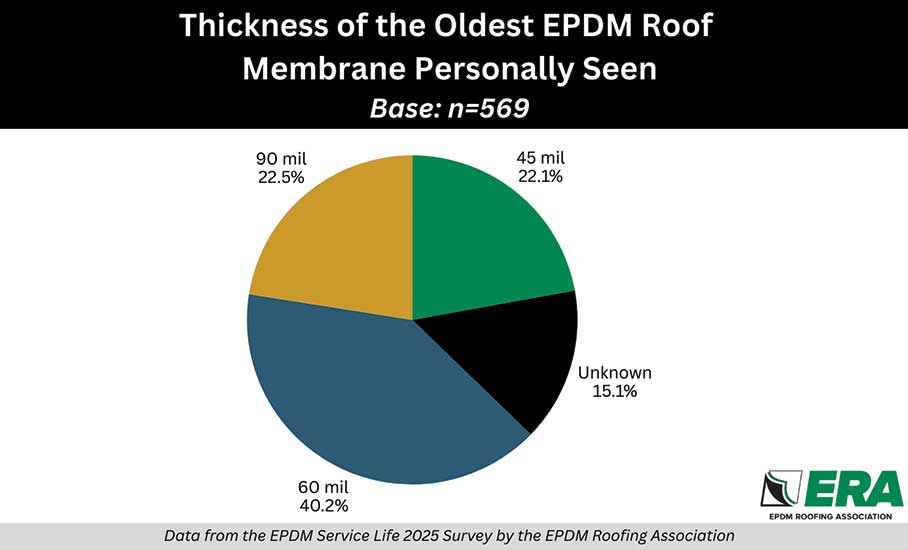

Membrane thickness varied widely among survey respondents who reported extended EPDM membrane service lives: 126 (22%) witnessed 45-mil-thick membranes achieving extended service lives; 229 (40%) observed 60-mil-thick membranes achieving extended service lives; and 128 (22%) observed 90-mil-thick installations achieving extended sevice lives. This distribution suggests that though thicker membranes may offer longevity advantages, even thinner commercial EPDM membrane products can deliver decades of reliable performance.

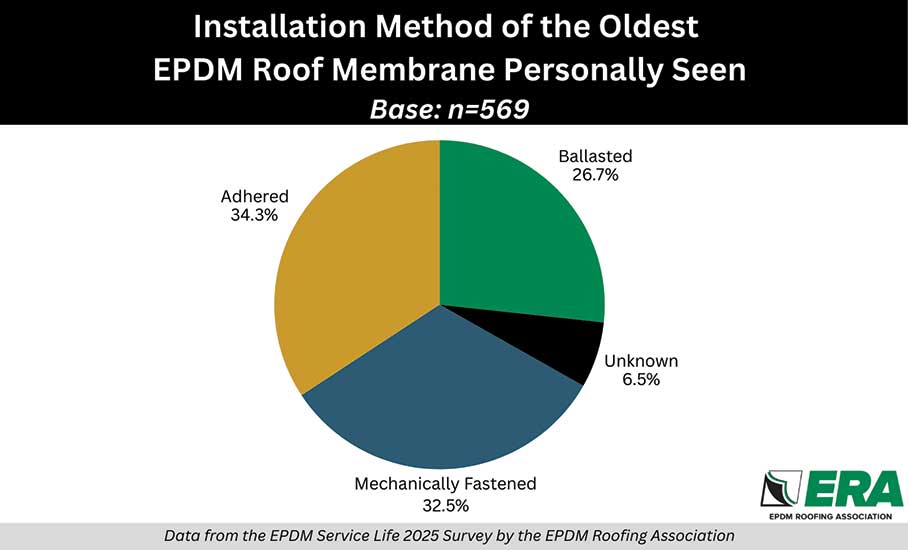

Attachment methods for the oldest membranes were distributed across three primary installation types: 195 (34%) respondents cited adhered systems; 185 (32%) reported mechanically fastened installations; and 152 (27%) cited ballasted roofs. This suggests all attachment methods can support extended membrane service life.

The survey’s open-ended feedback section revealed how roofing professionals think about EPDM performance and what factors they believe drive longevity. Following strength of the membrane, installation quality emerged as the dominant theme.

The recurring message from professionals: EPDM roof system longevity stems from a combination of material durability, ultraviolet stability and crosslinked structure but only when fundamental installation practices around seams, flashings and penetrations are properly executed.

What the research says

The observations captured in the 2025 survey align with systematic research examining EPDM membrane performance conducted since 1991.

The systematic study of EPDM membrane service life began when roofing science researchers B.D. Gish and K. Lusardi conducted landmark research in 1991 that examined 45 EPDM membranes ranging from three to 17 years old collected from 13 U.S. states. Their work tested fully adhered, mechanically attached and ballasted systems—all manufactured between 1974 and 1988, representing the first generation of commercial EPDM membrane roofing in North America.

Researchers found 87% of sampled roofs exceeded ASTM D4637, “Standard Specification for EPDM Sheet Used in Single-Ply Roof Membrane,” criteria for new EPDM membrane. They found no clear correlation between age and properties for roofs ranging from four to 12 years old. Surface appearance proved unhelpful when determining membrane age; the membranes were more durable than standard accelerated aging tests suggested.

By 2004, sufficient time had elapsed for re-searchers to examine EPDM membrane installations approaching and exceeding quarter-century service lives. Thirty-three membranes (45- and 60-mil-thick) up to 26 years in service were collected from nine states across diverse U.S. climate zones and tested.

The findings reinforced and extended the 1991 conclusions. All tested membranes remained “watertight and functional” after 17 to 26 years of service. Tensile strength and tear resistance for ballasted and exposed roofs exceeded ASTM D4637 specifications for new and heat-aged membrane performance, which directly validates the 25- to 29-year service life expectations cited by 2025 survey respondents for 60-mil-thick EPDM membranes.

In 2003, Jim Hoff, president of TEGNOS™ Research Inc., Tubac, Ariz., published a white paper, “EPFM Roof System Performance: An Update of Historical Warranty Service Costs,” regarding the results of a study that analyzed 3 billion square feet of EPDM roofs and the timing, costs and types of services performed by manufacturers during the warranty periods. The study demonstrated declining EPDM warranty costs as detailing improved, proving system execution, not membrane changes, reduce failures.

Also in 2004, Das Kunststoff-Zentrum, a research and development organization in Würzburg, Germany, published results from testing 39 EPDM membrane roof samples in service for up to 30 years. None of the samples showed visible indications of material damage, and all were fully performing their roofing function.

In 2010, the EPDM Roofing Association released results from testing five membrane samples with 28 to 32 years of in-service life—all 45-mil-thick membrane samples were installed between 1978 and 1982. Four samples were ballasted systems; the fifth was fully adhered. Locations included the Midwest and North Carolina, representing harsh winter climates and hot, humid summer conditions.

The results demonstrated EPDM membranes not only reach but easily exceed the 25-to30-year service life range. All five in-situ-aged samples exceeded the minimum standard tensile strength for newly manufactured membranes.

Survey and research converge

The convergence between field experience and laboratory testing provides powerful validation.

The 2025 survey respondents believed thicker membranes outlast thinner ones. The 160 professionals expecting 40-plus years from 90-mil-thick adhered systems compared with 70 of them expecting similar performance from 60-mil-thick mechanically fastened installations demonstrates this conviction.

Although published research hasn’t systematically compared different thicknesses under identical conditions over extended periods, available data supports professional intuition. The German study included 45- and 60-mil-thick membranes reaching 30 years, and the EPDM Roofing Association studies documented 45-mil-thick membranes at 28-32 years still meeting standards for new material.

If 45-mil-thick membranes can reach 30-plus years, the industry’s expectation that 60- and 90-mil-thick products will proportionally outlast 45-mil-thick products appears grounded in reasonable extrapolation from material science fundamentals.

The 2025 survey results showed slightly higher service life expectations for adhered systems compared with mechanically fastened installations of equivalent thickness. This preference aligns with research findings.

The 2025 survey respondents’ preference for adhered systems likely reflects accumulated experience with how different attachment methods perform over decades of service, including factors beyond pure membrane longevity such as adherence to manufacturer maintenance protocols.

Perhaps the strongest convergence between professional experience and research findings concerns installation quality. The 2025 survey respondents emphasized EPDM membrane failures typically stem from improper installation. The 1991 studies documenting successful 20-, 25- and 30-year service lives implicitly tested properly installed systems—membranes that survived long enough to be sampled and tested represent installations where fundamental details were executed correctly.

The message professionals delivered through the 2025 survey responses matches what research implies: Membrane longevity depends primarily on proper execution of the installation details that protect the membrane and maintain system integrity.

Throughout four decades of single-ply membrane research, scientists have used accelerated aging—subjecting membranes to elevated temperatures to predict long-term performance. However, laboratory-aged samples consistently underestimate EPDM membranes’ real-world durability. Field-aged EPDM membranes, by contrast, often maintain or increase tensile strength and show stable elongation (the percentage by which a membrane can stretch before breaking) for extended periods. Heat aging in a laboratory simply cannot replicate the complex interplay of ultraviolet exposure, thermal cycling, moisture and other environmental factors EPDM membranes experience on actual roofs.

This is why professional field experience has become invaluable when assessing EPDM membrane service life. The 2025 survey observations from experienced contractors and consultants who represent decades of accumulated experience collectively report EPDM membranes outperform laboratory predictions.

What we still need to learn

Despite the strong alignment between professional observations and research findings, significant knowledge gaps remain.

Most published studies examined membranes manufactured between the mid-1970s and late 1980s. Modern EPDM membrane formulations have evolved, incorporating improved compounding technologies, more consistent manufacturing processes and refined reinforcement materials.

The 2025 survey respondents reporting 40- and 50-year-old EPDM membrane installations are observing the same generation of membranes tested in published research. Although physical testing can determine current properties, converting those measurements into accurate predictions of remain-ing years requires understanding degradation rates under specific conditions—information not yet available with sufficient precision.

Current research initiatives aim to address these gaps. A forthcoming pilot study conducted by an independent building science and testing company commissioned by the EPDM Roofing Association will examine in-situ aged EPDM membranes manufactured and installed in the 2000s, providing data about modern formulations. Additional research will subject already field-aged samples to further accelerated laboratory aging, working to improve correlation between laboratory predictions and field observations.

Efforts are also underway to develop standardized field assessment protocols that would allow roof consultants to estimate remaining membrane life through a combination of visual inspection, nondestructive testing and limited sampling. Such tools would formalize the pattern-recognition experienced professionals have developed through decades of field observations.

Science validated by experience

The roofing professionals who participated in the EPDM Service Life 2025 Survey aren’t speculating about membrane longevity—they are reporting what they have observed firsthand over decades of practice. When nearly 50 respondents cite 40-year-old EPDM membrane installations as reasonable and more than 20 report seeing 50-year-old EPDM membranes on roofs, they are documenting a level of durability many building materials cannot match.

What makes these observations particularly credible is how closely they align with systematic research. The professional consensus around 25- to 40-year service life for standard configurations matches precisely with published testing of membranes at those ages. The reported observations of 40-plus-year installations extend logically from research documenting 28- to 32-year-old membranes still meeting standards for new material. The emphasis professionals place on installation quality echoes the implicit message of research studies: Properly installed EPDM membranes have proven remarkably durable for decades.

As one survey respondent succinctly summarized: “EPDM roofs properly designed and installed and appropriately maintained have some of the longest service lives I’ve seen.”

ELLEN THORP

Executive director

EPDM Roofing Association