Before you continue to read this piece, know that I anticipate a symphony of dismay from many general contractors, construction managers, design architects and developers who may resist what I am about to say. I understand the allure of a flat roof deck is undeniable. It is easy to visualize and draw and creates a level line for wall elements adjacent to the deck to follow; no ugly curbs peek over the walking surface.

However, the consequences of a flat roof deck are significant, permanent and should not be ignored.

The problem with flatness

First, let’s establish situations where the lack of slope can cause serious issues. Apartment buildings, high-rise condominiums, hospitals, corporate office buildings, hotels and other public buildings sometimes have outdoor spaces that are generally accessed through the building. These spaces usually are above interior building areas, parking garages or utility spaces. Often, these areas are meant to be accessed by building occupants and have a level walking surface such as pavers, a wood or synthetic lumber walkway or a concrete slab with drainage occurring below the visible surface. Typically, windows, doors or curtain walls visually connect amenity decks to the interior.

Outdoor rooftop spaces often have aesthetic and functional elements such as planters, sitting areas, wind or visual screen walls and focal elements such as fire features, trellises or fountains.

Sometimes deck elements require functional utilities such as electrical service, gas lines, irrigation and/or potable water piping. Some equipment may require structural attachment and electrical, plumbing or gas utilities. Also, there may be decorative vegetation, trees and/or aesthetic overburden. In short, a lot is going on. Now think about rain falling and disappearing below the surface of these complex rooftop elements. Where does it go?

Amenity decks are designed with a roof system beneath the walking surface and surface elements. Most commonly, these systems are designed to allow water to filter through surface elements like pavers, walkways, vegetation, planters, etc. Just below the surface may be pedestals for pavers, thermal insulation, supports for walkways, structural components or drainage mats. At the bottom of the system is a roof membrane layer (the drainage plane) applied to a structural deck. It is meant to manage water where it exits through drains or scuppers. Less commonly, the drainage plane protects above-deck roof insulation and the roof system may include a vapor retarder installed above the structural deck.

Most low-slope roofs are not meant for people to walk on other than for maintenance but have elements atop the drainage plane. The most common is nonoccupiable vegetative roofs, typically with growth medium and low-growing vegetation such as sedum, meant to delay stormwater runoff, increase habitat for birds and insects, mitigate urban heat islands and provide other benefits. As with amenity decks, water is meant to filter through surface elements to a drainage plane.

Tapered insulation

In most jurisdictions, the minimum roof system slope is ¼ of an inch per foot for new construction. A common approach to creating roof system slopes for low-slope commercial roofs is to use tapered foam insulation boards, most often polyisocyanurate.

If a structural deck is flat, the thickness of the overall insulation increases by 1 inch for each 4 feet of distance between drainage points and edges of catchment areas for each drain/scupper. A thickness of 12 inches or more can occur with such systems, and careful coordination of the location of drainage points and the roof system tapered plan is necessary to control overall roof system thickness. Special attention should be given to roof areas with maximum insulation thickness limits, such as door thresholds, windowsills, counterflashing elements and rooftop equipment-related elements.

Having a flat drainage plane below the surface is tempting as it dramatically simplifies the design because most walking surfaces also are meant to be level. But when it rains, water filters through surface elements, reaches the roof membrane and spreads until the entire surface is covered and the water level rises. This rising water imparts an additional load onto the roof deck (5.2 pounds per square foot for every inch of thickness). Although the structural designs of roof decks are required to account for the weight of ponding water, this load causes deflection of the roof structure, resulting in added load and, in extreme cases, “ponding instability,” or instability in the structure caused by progressive deflection. In the worst case, it can result in roof system collapse.

Eventually, water will reach drainage points on the deck and flow into the storm drainage system. Any water that doesn’t get to a drain stays on the roof surface until it evaporates. In colder weather, it may freeze until temperatures rise.

The problem with this configuration is flat roofs aren’t truly flat. The ability to construct a completely flat roof deck is hindered by deflection. In addition, back slope (when roof decks slope away from drainage points) and low points inevitably occur. This results in standing water or accelerated deterioration of roof surfaces and flashings and debonding of the roof membrane from the substrate if water flows against building elements and away from drainage points. Debonded membranes are especially problematic as they allow a path for water to travel uncontrolled and in direct contact with surfaces not designed to resist moisture damage.

During heavy rainstorms or snowmelt, water on roofs often rises quite high as it waits to flow through drainage points. This allows moisture to reach higher onto flashings and sometimes above the roof system flashings onto surfaces not meant to handle the flow.

Over time, water’s ability to flow across roof surfaces slows because debris enters the drainage layers and they compress over time. Slower flow allows water to reach even higher during heavy precipitation (this is known as rain load). Ultimately, this scenario results in moisture routinely reaching areas of the building not designed to handle rain load and moisture infiltration into building spaces. If roof system defects exist, water also infiltrates at those weak points.

Slope makes it better

Think of a bathtub with water sitting in the bottom; the bathtub becomes full faster when new water is added because there already is water in the bathtub. A roof system operates the same way. Now imagine adding a slope to that bathtub. With slope, water never sits stagnant at the bottom because it always is moving toward the drain. Similarly, when it rains, slope makes it less likely for water to overflow a roof system as it waits to drain. And if there are roof system defects, the defects are not constantly under water. I believe the argument for slope is clear, but I suspect there may still be skeptics. More flashing height is needed when sloped roofs are installed because supports must be tapered or of varying heights to achieve level walking surfaces. When tapered insulation is used to create slope, insulation can get quite thick at the high point of the roof system (top of the slope), especially when there are few drainage points. These realities add costs to new construction projects because of the need for taller curbs, parapets, equipment supports, etc.

In addition, roof system manufacturers routinely express confidence in their products and offer reassurances their roofing materials are designed to hold up under harsh conditions such as constant underwater exposure. I see general contractors pressuring design architects and installing contractors to accept zero slope as a cost-saving measure or when the designed slopes don’t quite happen during construction. I understand ensuring proper slope competes with thousands of other issues during a construction project and does not often reach the top of the list of concerns. But what is frequently overlooked is building codes generally require slope for surfaces that receive rain loads, but it’s not as evident in the code as it should be.

Code requirements

Most U.S. jurisdictions adopt model building codes, which are developed nationally with input from code specialists, technical and safety subject matter experts, material manufacturers, building code officials and the general public.

State and local building departments and agencies adopt model codes and sometimes amend the requirements to suit local conditions or practices. The dominant model building code used by state and local jurisdictions is the International Building Code® produced by the International Code Council. IBC is updated every three years; 2024 is the current edition.

IBC defines a roof assembly as “a system designed to provide weather protection and resistance to design loads … .” In other words, roofs must comply with the code’s weather protection and structural requirements. As discussed previously, systems below the walking surface of amenity decks function as roofs because they are designed to handle precipitation and design loads and, therefore, must be designed as such.

Slope requirements are in IBC’s Section 1507. There are requirements for common types of commercial roof systems such as built-up, polymer-modified bitumen, single-ply, spray polyurethane foam and liquid applied. For each roof system type, minimum material standards are referenced in the code and established as a minimum requirement. Usually, the referenced standards are active, meaning a committee of experts considers updates and modifications based on current industry conditions and technologies. Active standards are republished with regular updates.

IBC Section 1507 addresses slopes for roof types commonly used in low-slope situations, such as under overburden on amenity decks. The listed minimum slope requirement is ¼ of an inch vertical per 12 inches horizontal (1/8 of an inch vertical for coal-tar roofs). Rain load requirements for roofs are in IBC Section 1611 and referenced in IBC Section 1502.1.

IBC Section 1512 indicates whether a roof is re-covered or replaced; the reroof must comply with the requirements for new construction with an exception noted for roof slope. This section indicates replacement roofs are considered adequately sloped when they provide “positive roof drainage.” IBC defines positive roof drainage as “a design that accounts for deflections from all design loads and has sufficient additional slope to ensure that drainage of the roof occurs within 48 hours of precipitation.” The section also references rain load requirements in IBC Section 1611.

Although the slope requirements noted in the previous sections are clear for specific roof system types noted in IBC Section 1507, there often is confusion regarding roof system types not explicitly mentioned in the code. Materials identified generically as “waterproofing” are frequently used, and the most common waterproofing type for roofs with overburden are hot- or cold-applied rubberized asphalt membranes. This type of material is not mentioned in the code and does not have an active material standard. Although some people believe unmentioned materials are not subject to IBC Section 1507 requirements for slope, this is not the case.

The code provides guidance for roofing materials not mentioned in IBC Section 1507 and for any situation where a construction material not explicitly addressed in the code is installed. IBC Section 104.2.3 addresses alternative materials, design and methods of construction and equipment and states: “The provisions of this code are not intended to prevent the installation of any material or to prohibit any design or method of construction not specifically prescribed by this, provided that any such alternatives have been approved.”

IBC defines approved as “acceptable to the building official.” IBC Section 104.2.3 establishes alternative materials or use must meet the code’s intent and function equivalently to those materials or designs identified in the code.

To summarize, slope is required in all cases because slope is required for all items mentioned in the code, and any unmentioned material must be used similarly.

Some jurisdictions have amended model code language to allow for certain roofing products to be installed at zero slope.

District of Columbia Building Code Section 1507.18—Hot-applied rubberized-asphalt roofing and Denver Building and Fire Code Section 1507.19—Hot-applied, Reinforced Rubberized Asphalt Roofing indicate such material is not required to have a minimum design slope and must comply with the Canadian General Standards Board Standard CAN/CGSB-37.50-M89—Hot-Applied, Rubberized Asphalt for Roofing and Waterproofing. The standard was last updated in 1989 and is listed as “withdrawn.” CGSB includes the following note on its website regarding withdrawn standards: “Note: The information contained in these withdrawn standards was originally developed pursuant to a voluntary standards development initiative of Canadian General Standards Board (CGSB). The content therein may no longer represent the most current, reliable, and/or available information on these subjects. CGSB hereby disclaims any and all claims, representation or warranty of scientific validity, or technical accuracy implied or expressed respecting the information therein contained. CGSB shall not take responsibility nor be held liable for any errors, omissions, inaccuracies or any other liabilities that may arise from the provision or subsequent use of such information.”

The Denver code contains the following exception: “Areas of roofs used for occupied roofs, vegetative roofs, roof gardens or other similar purposes, shall not be required to have a design slope provided a permanent electrical conductance breach detection method for testing the membrane is installed in addition to a drainage mat.”

Although requiring a permanent breach-detection method to be built into a roof system is a sensible precaution, should a breach occur, a building owner would incur the costs of uncovering the affected areas so repairs could be made. A manufactuwrer’s material warranty typically does not address moving overburden so repairs can be made, and breach-detection methods may not detect moisture moving below a debonded membrane, a common issue with membranes installed on zero-slope decks.

NRCA's stance

Although building codes establish minimum standards, it’s helpful to understand other viewpoints, such as The NRCA Roofing Manual.

The NRCA Roofing Manual has been in publication since 1971 and is updated on a four-year cycle. Each year, an update for one of the manual’s four volumes is published.

The NRCA Roofing Manual: Membrane Roof Systems—2023 has the following guidance regarding roof slope: “NRCA recommends roof systems be sloped to provide positive drainage for a finished roof system. Additionally, for new construction, the roof system should meet the building code requirements for minimum roof slope for the specific roof covering type.” NRCA’s guidance aligns with model building codes, and the organization advises that a slope be provided in all cases.

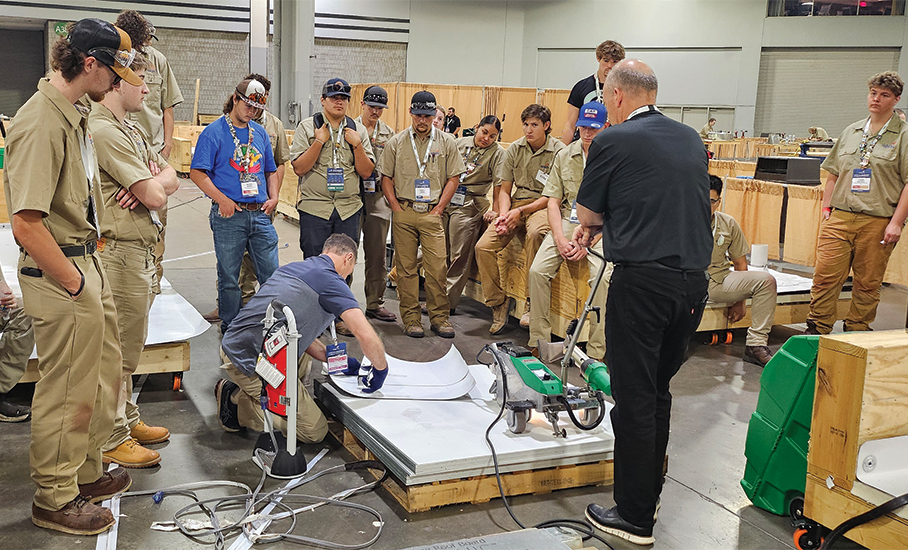

In addition, NRCA recommends all roof system installations have a quality control plan, especially those that will be covered with overburden. Roofing contractors should explain their quality control plans at preconstruction meetings, and general contractors should prioritize interactions with other subcontractors whose work is adjacent to roof areas.

NRCA’s Quality Control and Quality-assurance Guidelines for the Application of Membrane Roof Systems discusses two methods of achieving quality.

Quality control is identified as being performed by roofing contractors. An individual present during the entire roof system installation should have the authority to correct noncompliant work. This person may be a working crew member and should completely understand the roof system being installed. Quality control should happen on every roofing project.

Quality assurance occurs in parallel with quality control and is the responsibility of building owners, typically through their representatives, such as architects, engineers, roof consultants, construction managers or general contractors. Sometimes, manufacturers also perform quality assurance as part of their warranty issuance procedures.

Those performing quality assurance should understand the roof system being installed and the contractor’s installation process; they should have an established method of informing contractors when noncompliant work is observed so timely corrective action by the contractor can occur. A helpful reference is ASTM D7186, “Standard Practice for Quality Assurance Observation of Roof Construction and Repair.” The standard’s scope includes procedures for performing visual monitoring of roof construction, establishing guidelines for quality assurance observation practices, and defining the role and responsibilities of the quality assurance observer.

For more information, go to shop.nrca.net and astm.org.

Although both codes allow hot-applied rubberized asphalt roofing to be installed without slope for drainage, it is important to note Carlisle Construction Materials, Carlisle, Pa., requires slope in its guide specification indicating “concrete shall be cured at least 14 days and shall be sloped for proper drainage.”

Following manufacturers’ written installation instructions is required in most building codes, including those in the District of Columbia and Denver. The amendments noted seem designed to benefit the original builder while downstream building owners are subject to adverse effects, related costs and disruptions of zero-slope roofs over the long term.

Long-term issues

As a forensic architect, I have seen firsthand the ramifications of zero-slope amenity decks. Often, the first sign roofs are nearing the end of their service lives is when leaks begin to appear. Leaks also can happen in areas where roofs are installed improperly.

A sloped system is much easier to evaluate when leaks happen. When roof surfaces are sloped, investigators strategically add water in sequence starting at low points. Because water movement below the surface is predictable and will follow the slope below the surface, defective areas can be more easily identified and overburden only needs to be moved to expose the problem areas so repairs can be made. This saves cost and reduces disruption time.

Without a slope, water spreads out in all directions once it reaches roof surfaces below surface elements. Water entering a system can cause a leak at any point, making it challenging to water-test flat decks effectively. Large overburden areas often need to be removed for an effective leak investigation. This is expensive and disruptive. When defects are found and repaired, it is frequently difficult to confirm the leak has been resolved because the entire roof area must be flooded to confirm all infiltration paths have been found, and it may be difficult or impossible to replicate a rainstorm. This frustrates building owners as leaks may reoccur after heavy rain or snow melt, and leaks usually become more intense as roofs age.

Every building project needs people who understand slope and drainage and advocate for effective roof system designs.

The reality is buildings constructed with flat roof surfaces below overburden will plague building owners with costly maintenance and repair costs that increase over time. These additional costs and related disruptions generally can be avoided by designing appropriately sloped drainage planes as part of their original constructions. Any cost savings achieved by choosing a flat roof surface versus a sloped one are often eclipsed by additional operating and maintenance costs incurred over the service life of a building.

Stick with slope

In a new construction scenario, in my experience, the best long-term configuration is when a structural deck is sloped to drainage points. Ideally, this means the slope is built in, and any roof system installed above will naturally drain properly. If a structural roof deck is built flat, slope must be added with above-deck elements such as cementitious toppings or tapered insulation. These above-deck solutions often work well assuming proper materials and attachment methods are used.

Architects and general contractors frequently leave the drainage scheme to be worked out during construction and rely on subcontractors to propose a slope design as part of the submittal process. This can work well when experienced subcontractors are involved and architects or specialty consultants thoroughly review before installation.

Whichever slope strategy is used, the design must accommodate the entire thickness of a roof system, as well as related components such as insulation and various overburdens.

In reroofing scenarios, roof systems must accommodate existing conditions. Building owners with roofs constructed without slope or sufficient perimeter construction height often face challenging decisions. Changing code requirements has made compliant reroofing design even more difficult, especially the ever-thicker insulation required to meet energy codes. This is especially true for amenity decks with original designs that did not initially accommodate proper flashing heights.

I encourage design teams for new construction to have building enclosure specialists evaluate and optimize roof drainage designs during the design phase. Specialists also should assess the primary roof drainage system and secondary overflow drainage scheme to determine whether there is enough storm drainage capacity for the anticipated rain load. A proper drainage system reduces the height at which water rises during storms, gets water off a roof more quickly and ultimately imparts less stress onto the roof system’s elements.

Every building project needs people who understand slope and drainage and advocate for effective roof system designs in the chaos of the design process. Future building owners and users will thank you for it.

JASON WILEN, AIA, NCARB, CDT, RRO

Associate principal

Klein and Hoffman